On February 23, the 4th DME Dongguan International Machine Tool Exhibition was grandly held in Guangdong Modern International Convention and Exhibition Center, Topcentral® and Ningbo Younom Machinery Co., Ltd. jointly launched a new injection molding machine. Topcentral®100% PCR leading materials Nairong®rPA6-S22N and IBISS® rABS-N115CG were processed on-site at the booth, attracting many industry insiders to come to understand and consult and conduct in-depth exchanges on the application of related products.

Topcentral® and Ningbo Younom Machinery Co., Ltd. jointly launched a new injection molding machine, aiming to export the company‘s core materials and system solutions to terminal manufacturers, help manufacturers improve production processes, and meet the needs of the market and users. In particular, IBISS® rABS-N115CG is the first 100% PCR zero-carbon rABS functional modification technology in the field of polymer materials in the world. 100% PCR zero-carbon food-grade IBISS® and high-performance, high-stability, green and low-carbon health and environmental protection BPA obtained through multi-dimensional independent design and innovation Free IBISS® rABS is certified by the authoritative organization TUV, which reduces carbon emissions by 83.21% compared with native ABS, and adopts carbon forest sink and green trading to finally achieve zero carbon emissions, and then provide zero-carbon product system solutions for global strategic partners. In addition to the two products highlighted in this exhibition, all products from Topcentral® meet the requirements of many international certifications and regulations such as SCS GLOBAL, UL, GRS, TUV, etc., and have obtained the product carbon neutrality certification issued by TÜV Rheinland, so as to realize the high-value recycling of waste plastics.

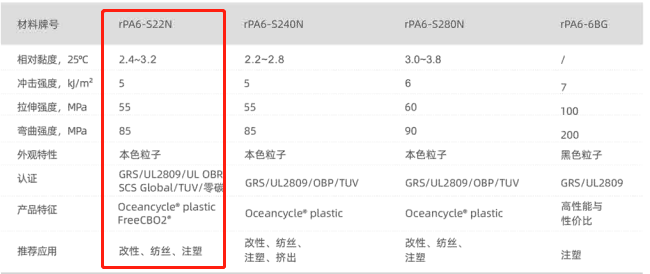

Nairong®rPA6

PCR PA6 particles prepared based on post-consumer recovered fishing nets, automobiles, low-voltage electrical appliances, etc., after pretreatment and standardized granulation modification. The appearance is mainly natural and black, which can provide customers with customized products such as plastic recycling products, which can meet many needs in injection molding, modification processing, textile spinning, extrusion and other fields, and can provide a full range of customized system solutions according to customer special requirements.

Product parameters

Product brand

TC Post-Consumer Recycled®

Topcircle®

TcycleEP®

Nairong®

Oceancycle®

FreeCBO2® ("Zero" carbon)

Ocean Partner®

Product Features

1.Finely design and optimize the control of raw material sources and quality of rPA6 and Oceancycle®, strictly manage production and processing technology and technical quality standards, and achieve stable and sustainable product performance, which can realize the traceability of the whole industry chain;

2.The products are mainly white particle products, and the black particle products are mainly recycled glass fiber reinforced modified materials after consumption;

3. Provide carbon footprint, carbon emission accounting and other related data and certification;

4. It can reduce or reduce carbon emissions by more than 92.3%, and some products have achieved "zero" carbon [cradle to gate];

5. The product complies with RoHS/REACH standards and has passed GRS/UL2809/TUV/OP/OBP/FreeCBO2/carbon neutral/carbon footprint/SCSGlobal certification, and work together to build a pioneering and open Ocean Partner®;

6. High purity and transparency, extremely low yellowness and few black spots of impurities;

7. Provide "zero" carbon Oceancycle®FreeCBO2® ("zero" carbon) products;

8. According to customer customization requirements, provide a full range of customized system solution innovation solutions;

Application direction

The product is suitable for downstream deep processing modification and granulation, and can be made into various mechanical parts after modification, and is also suitable for injection molding, spinning and other applications.

IBISS®rABS

It is a plastic pellet prepared by recycling post-consumer products (including but not limited to home appliances, communication equipment, pipes, plates, coils, consumer electronics, etc.) through pretreatment and standardized granulation modification. According to different recycling sources and quality levels, design classification screening, technological innovation breakthroughs, performance optimization and high-quality automated production and processing provide customers with extruded and injection grade rABS particles. The company‘s products cover different sources of emulsion method and ontology method, and can provide colors including but not limited to natural color, black, gray, white and other different color systems. It can meet the different application needs of industry customers, and at the same time can provide a full range of customized system solutions and innovative solutions according to customer special requirements.

IBISS®rABS-N115CG

IBISS®rABS-N115CG products

Product parameters

Product brand

TC Post-Consumer Recycled®

Topcircle®

TcycleGP®

IBISS®

FreeCBO2® ("zero" carbon)

ITEcycle®

Product Features

1.Finely design and optimize the control of raw material source and quality of IBIS®rABS, strictly manage production and processing technology and technical quality standards, and achieve stable and sustainable product performance, which can realize the traceability of the whole industry chain;

2.Provide carbon footprint, carbon emission accounting and other related data and certification;

3. The product complies with RoHS/REACH/FDA standards and has passed GRS/UL2809/TUV/SCS Global/Oceancycle plastic/ITE/"zero" carbon certification;

4. It can reduce or reduce carbon emissions by more than 83.3%, and some products have achieved "zero" carbon [cradle to gate];

5. According to customer customization requirements, provide a full range of customized system solution innovation solutions;

6. Provide "zero" carbon IEBS®rABS & FreeCBO2®("zero" carbon) products.

Application direction

The products are suitable for downstream deep processing modification granulation, extrusion molding, injection molding, and can be widely used in home appliances, electrical appliances, automobiles, packaging, daily chemical products and other product parts.

At present, Topcentral® business segment is expanding, and in the future, it will strengthen exchanges and interaction in technology, strategy, industry resource integration and in-depth cooperation. Based in Zhejiang, Topcentral® radiates the whole country and exports to the world, providing innovative new material solutions with partners in various fields such as consumer electronics, petrochemical industry, intelligent manufacturing, and other home appliances.