Folder Material

Don‘t make the wrong choice

Keywords: PP material, recycled material Folder Material

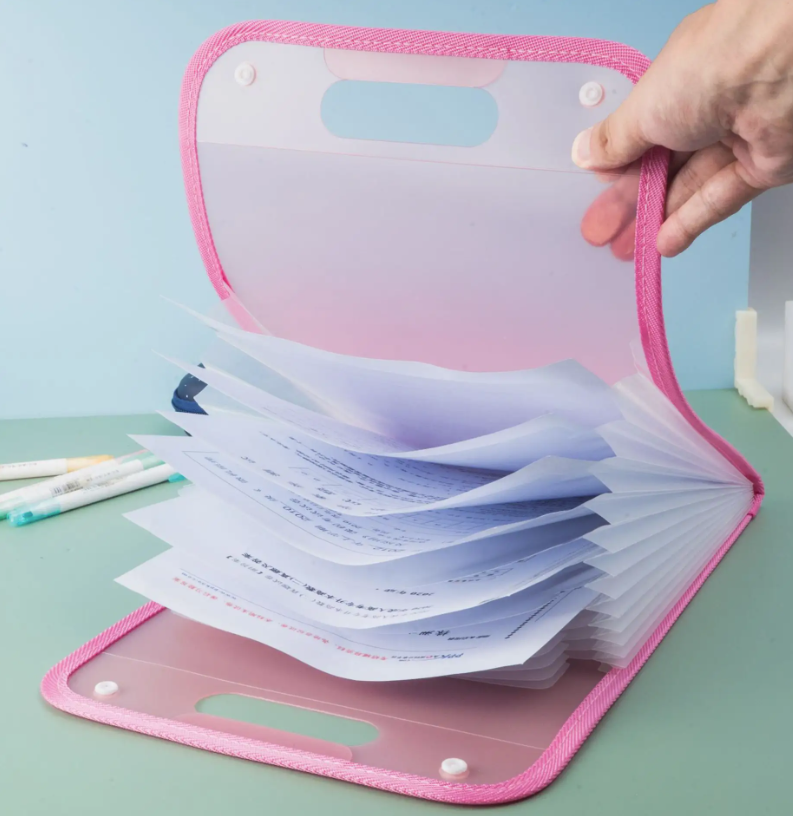

Folder, commonly used items for students and professionals. A good folder can effectively save files, store information and data in different categories, and help us quickly retrieve useful information, improving learning and work efficiency.

Although folders are common, they also require a lot of attention. Their appearance design, printing standards, size, material usage, product categories, and so on. Taking materials as an example, there are various materials such as PP, PVC, cardboard, and so on.

- PP material

Due to its wide range of use, it has become the most commonly used material in folders. Currently, most folders on the market are composed of PP materials.

advantage:

PP material has high hardness and is not easily deformed, good tear resistance, load-bearing performance, waterproof performance, heat resistance, corrosion resistance, wear resistance, drop resistance, scratch resistance, transparency, easy processing, recyclability, stable chemical properties, pure and non-toxic texture.

Disadvantages:

In low-temperature environments, performance decreases, aging occurs due to prolonged exposure to light, heat, and oxygen, poor coloring performance, and poor toughness.

- PVC material

PVC also has a certain degree of application in folders, but the amount used is not as high as PP material. Compared to PP material, PVC material is more flexible and generally used more in file bags.

advantage:

Good plasticity and corrosion resistance, good flexibility, less brittle, and adjustable material hardness.

Disadvantages:

Poor flowability, inferior processing technology to PP, and poor impact resistance.

- Paper material

This type of material is easy to print and can be written directly. It is most commonly used for archival preservation and is currently also used on cardboard clips.

advantage:

Durable, easy to print, anti-aging, long storage time, easy to degrade, more environmentally friendly;

Disadvantages:

Easy to burn, damp, and tear, with lower hardness and toughness than PP and PVC materials.

Compared to PP and PVC materials, paper folders are more suitable for long-term storage and less frequent retrieval and use in daily life, making them the most suitable for archival preservation.

Overall, PP materials have a more diverse range of usage scenarios, whether in academic life or the workplace. Moreover, PP materials are also easy to recycle. However, compared to PP raw materials, recycled PP has stronger properties than new materials in certain aspects, and can be targeted to improve the performance of certain attributes based on the specific usage environment of the folder. While enriching the usage scenarios of the folder, it better protects the environment, Achieve a combination of economic and social benefits.

On the other hand, the application of recycled materials is also in line with the trend, with the rise of consumer environmental protection concepts, support from national policies, and continuous innovation and development of recycled material technology. PCR plastic is constantly recognized in the market, and stationery manufacturers are laying out recycled materials in their own stationery products.

For example, Chenguang, as a stationery brand giant, solemnly promises to lead the sustainable development of the industry and make good stationery with warmth after joining the Global Sustainable Consumption Initiative. Chenguang stated that by 2025, sustainable selection of some key raw materials will be achieved, and 100% of key suppliers will meet Chenguang ESG guidelines. At the same time, incorporating green innovation into materials and design to achieve environmental goals such as reducing carbon emissions and unnecessary plastic consumption, among many of Chenguang‘s stationery products‘ green development strategies, including the use of recycled materials in folders.

But high-quality PCR materials are still relatively scarce in the market. As daily office and learning supplies, folders not only meet the needs of application scenarios, but also need to meet the requirements of non-toxic and harmless. What characteristics should standard PCR PP materials have?

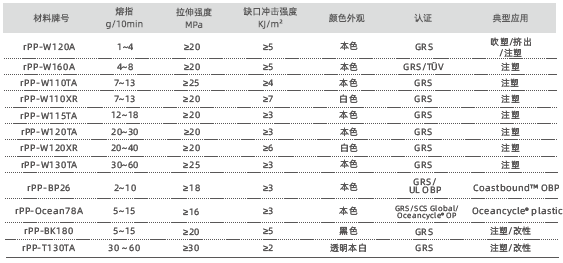

Topcentral® PCR Ploypoy ®

It is a plastic particle prepared from recycled and consumed products through processes such as pre-treatment and standardized granulation modification. Based on different recycling sources and quality levels, design classification screening, technological innovation breakthroughs, performance re optimization, and high-quality automated production and processing, providing customers with extrusion grade, injection grade blow molding grade rPP particles, colors including but not limited to natural color, black, white, etc., which can meet the different application needs of industry customers. At the same time, we can provide comprehensive customized system solution innovation solutions according to customer special requirements.

Product brand

Topcircle ®,

TcycleGP ®,

Ploypoy ®,

Oceancycle ®,

Coastbound ® OBP,

FreeCBO2 ® (Zero Carbon);

Product Features

Fine design and optimization control of the source and quality of rPP raw materials, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, and the ability to achieve full industry chain traceability;

The products are mainly made of high-grade natural white PP, covering designated colors such as (but not limited to black, white, etc.);

We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements;

The product complies with ROHS/REACH/FDA standards and has passed the GRS/TUV/SCSGlobal/Oceancycle® plastic/Coastbound® OBP certification;

Can reduce or reduce carbon emissions by more than 70%, and some products can achieve "zero" carbon [from cradle to gate];

Can provide relevant data and certification such as carbon footprint and carbon emission accounting, Oceancycle® plastic CertificateOBP Certificate。

Typical products

Application direction

The product is suitable for blow molded products such as cosmetic bottle bodies, extruded films/plates, various injection molded parts, and other fields.

——END——