Car seat

Recycled PET material

If waste plastic is added to luxury seats in cars, people will definitely find it a confusing behavior. However, the recycled plastic after processing has actually been applied to car seats!

As one of the top car brands, Audi has already "dried up" on its own seats! Audi‘s fourth generation A3 has already used recycled PET material on its seats.

Seat materials may not be the core components of automobiles, but they are also the components that come into contact with the human body the most. From this perspective, seat materials are still very important. Generally, the seat interior of a car is wrapped in leather, but compared to leather, another method is to use fabric to wrap the seats. What are the advantages and disadvantages of both materials?

- PET fabric material

At present, the mainstream use of seat fabric material is PET material. What are the advantages and disadvantages of this material, and how did it get favored by Audi?

advantage:

Not easily damaged, long service life, low repair difficulty, not prone to aging, strong friction, stable riding experience, low production cost, and good breathability;

Disadvantages:

Difficult to clean and poor heat dissipation.

- Genuine leather material

Genuine leather materials are generally used in luxury cars, and most of the leather used in household cars is imitation leather. Compared to PET fabric, what are the advantages and disadvantages of leather seats.

advantage:

Compared to fabric seats, leather seats do not allow dust to penetrate deep into the seats, making cleaning more convenient and providing good heat dissipation;

Disadvantages:

The surface is prone to loss, aging, smoothness, low friction, and poor breathability;

Whether it is fabric seats or leather seats, it is evident that their advantages and disadvantages are surprisingly opposite. This can precisely meet the needs of different car owners, regardless of the material, it doesn‘t matter who is good or bad. But the current trend is that in the future, car brands will definitely strengthen the use of recycled materials in vehicles as commodities. More and more policies have shown that the more low-carbon and environmentally friendly goods are, the more they will receive support from the government and the market. This is an inevitable trend for sustainable development.

Taking the fourth generation A3 of Audi as an example, the fabric of the seats in this vehicle is made of recycled PET. At the same time, this is the first time Audi has used secondary materials to make the seat interior. It is understood that 89% of the textile used in the seats in this vehicle is made of recycled PET bottles, which have the same quality, feel, and appearance as traditional textile interiors.

Regenerated PET, as the most common recycled material for seats, is used for Polestar Star seats and modern car Ioniq 6 seats. But their requirements for recycled materials can also be said to be very strict, and the general quality is difficult to meet their requirements. Therefore, they will choose to collaborate with professional recycling enterprises to achieve the ultimate in every detail of the vehicle, so that the PCR materials jointly developed truly meet their ideal usage standards. In the industrial chain, it is very common to entrust professional tasks to professional enterprises, and Topcentral® It is such a professional recycled materials enterprise, with PCR PET as the backbone ® One of the core products of, can meet the different application needs of industry customers, and can provide comprehensive customized system solutions and innovative solutions according to customer special requirements.

Topcentral® PCR TC-Rester® (Di Estete) ™)

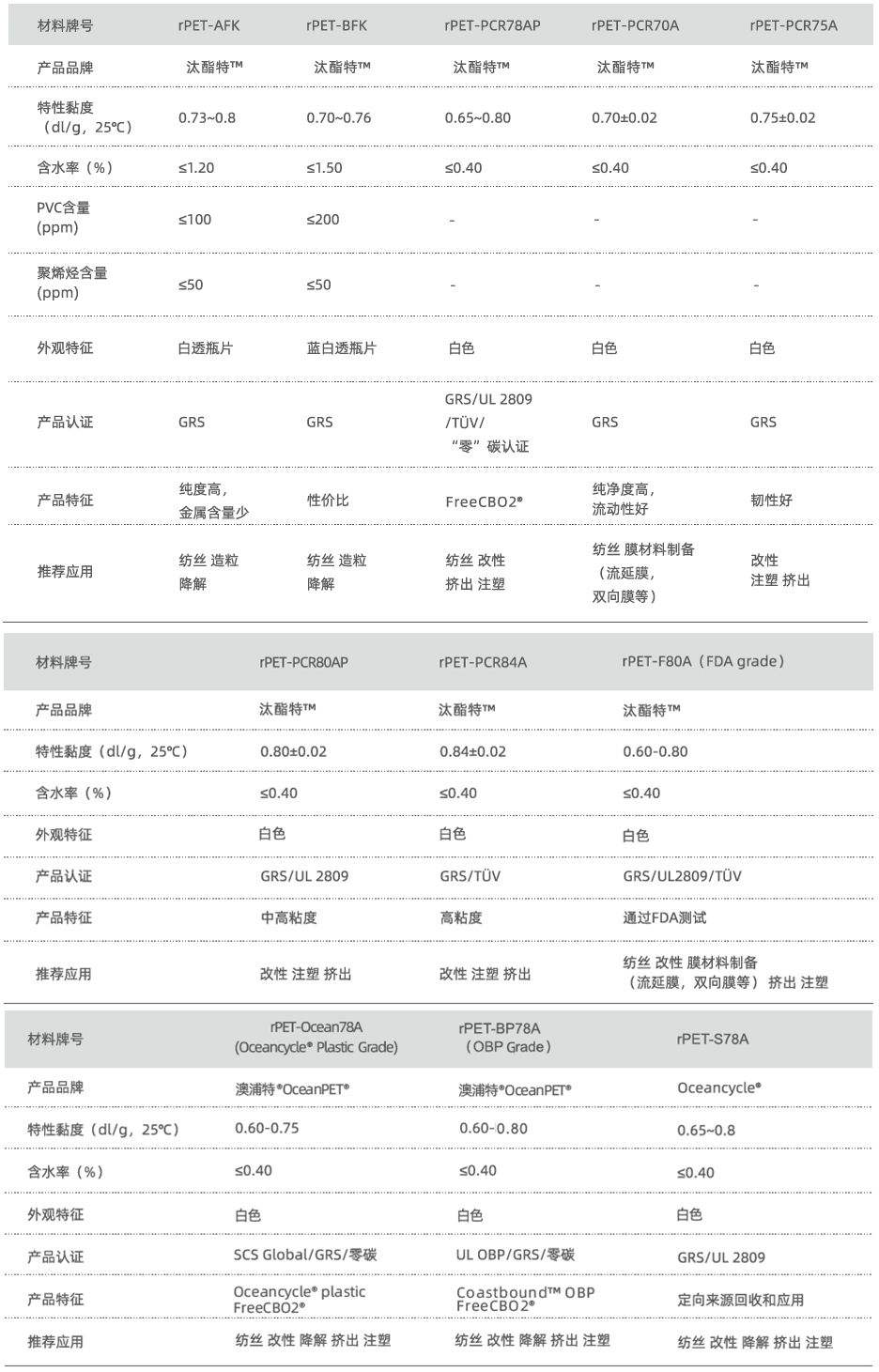

It is based on recycled water bottles after consumption, preprocessed to obtain rPET bottle chips or extruded modified rPET particles. Based on different recycling sources and quality levels, design classification screening, technological innovation breakthroughs, performance re optimization, and high-quality automated production and processing, providing customers with extrusion grade, casting film grade, bi-directional film grade, blow molding grade, and injection molding grade rPET particles, covering brand names such as medium to low viscosity, medium viscosity, and high viscosity. The product meets RoHS/REACH standards and has passed GRS/TUV/UL2908/SCS Global certification. Some products have passed FDA testing. At the same time, we can provide customers with Oceancycles for OBP recycling and OBP recycling ® Product series. It can meet the different application needs of industry customers and provide comprehensive customized system solutions and innovative solutions according to their special requirements.

Product brand

Topcircle®,

TcycleGP®,

TC-Rester®,

FreeCBO2® ("Zero"Carbon),

Aopu Te® ,

Ocean PET®,

Textcycle®,

Oceancycle®,

Coastbound® OBP,

Lakecycle®,

Ocean Partner®;

Product Features

Fine design and optimized control of diester ™ TC-Rester® RPET and Aopu Te® The source and quality of raw materials, strict management of production and processing processes, and technical quality standards, stable and sustainable product performance, can achieve full industry chain traceability;

High purity and transparency, product meets RoHS/REACH standards, and has passed GRS/UL2809/UL OBP "zero carbon" FreeCBO2®/ Carbon footprint/SCS Global/carbon neutrality certification, and some brands passed the FDA test;

Provide satisfaction for Oceancycle® OBP and Coastbound® OBP certified Aopu Te® Product, jointly building an Ocean Partner®, Ocean Partners ™ Circular Green Plan;

Provide "zero" carbon diester ™ TC-Rester® rPET,Oceancycle®, Aopu Te® FreeCBO2® (Zero carbon products)

Can reduce or reduce carbon emissions by over 77.7%, and some products have achieved "zero" carbon [from cradle to gate];

We can provide relevant data and certification such as carbon footprint and carbon emission accounting, and provide comprehensive customized system solutions and innovative solutions according to customer customization requirements;

Typical products

Application direction

RPET particle cover with medium to low viscosity (0.70dL/g), medium to high viscosity (0.75dL/g and 0.8dL/g), high viscosity (0.84dL/g), and the special sticker (0.85dL/g-1.1dL/g) launched in 2023 can be applied in multiple application fields such as film, sheet, packaging containers, and chemical fibers.

-END-