At present, it is midsummer, and in recent days, heatwaves have been coming one after another. As soon as the air conditioning stops, everyone will be sweating profusely. Water is also a incessant stream of water. In winter, it takes several days to finish a bucket of water. In summer, the water that was just changed in the morning in the editor‘s office is consumed in less than a day, and after drinking it, it changes again. Within a few days, the bucket becomes a large pile.

Then the editor curiously checked: How long can the bucket last? Can it be used indefinitely?

The answer is as follows:

PC is the main material used as a drinking water bucket, with a lifespan and frequency of use. It is understood that China produces over 100 million PC water buckets annually. Under normal circumstances, the lifespan of new buckets cannot escape 3 years. If used frequently, new buckets will be scrapped after 100 uses, while China has scrapped over 20 million drinking water buckets annually.

With this answer, the editor has a new question: summer is a high incidence period for bucket scrapping. How should these discarded buckets be used and what industries are they mainly used in?

As a directly recyclable bucket, PC buckets can easily withstand high temperature sterilization above 100 ℃. According to the "Quality Packaging Drinking Water Enterprise Production Hygiene Standards" implemented on May 1, 2004 in China, recycled drinking water buckets must be made of PC, and new buckets can generally be directly used after high-temperature disinfection, while other drinking water buckets become PCR PC materials and flow into other industries, The automotive and home appliance industries are the main application areas for recycled PCs.

It is worth noting that drinking water buckets, as food grade materials, have a wide range of applications after being recycled from the consumer market, making them ideal materials for recycled materials. Low carbon, as one of the important issues surrounding recycled materials, often provides systematic and comprehensive material creation solutions based on customers‘ unique requirements in the face of differentiated requirements. Through technological means and process methods such as recycling, innovative research and development, modification research and development, and standardized granulation, the target performance is achieved, enabling the recycled water bucket to truly achieve the best use of its resources.

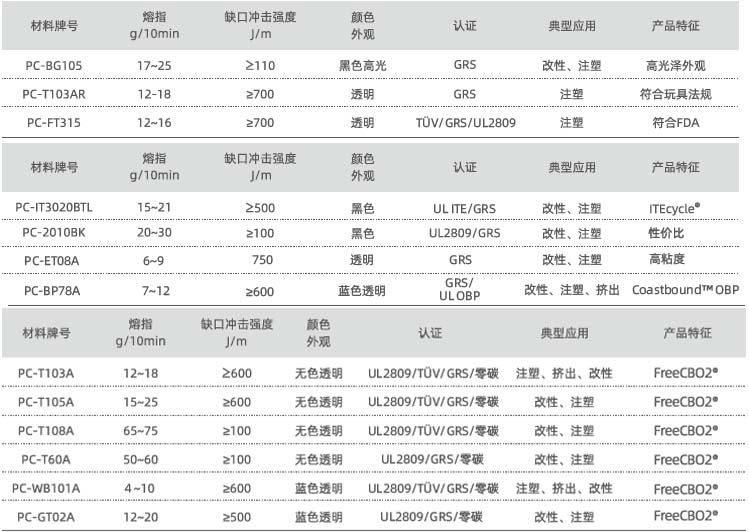

For example, Topcentral® The PC-WB01, PC-WB02, and PC-WB03 series of products are made from recycled water barrels that are dark and transparent after consumption. They can be applied to solar panels, storage boxes, partitions, and modifications. In addition, Topcentral ® And the zero carbon product brand of the bucket, PCR PC ® PC-WB101A, which has a clear Carbon footprint and has obtained Carbon footprint certification, has achieved product carbon neutrality through carbon quota compensation and obtained a carbon neutrality certificate (issued by TUV certification). The brand conforms to PCR product certification such as GRS/UL2809/TUV. It is a perfect product solution integrating excellent performance, complete PCR certification system scheme, Carbon footprint certification and carbon neutrality certification. Topcentral ® All PCR PC series products adopt a green, low-carbon, and environmentally friendly system solution to enhance material recycling while achieving diversified use of products, with wider applicability, greenery, and environmental friendliness.

Topcentral ® PCR PC ®

It is a kind of plastic particle prepared through pretreatment, standardized particle coating modification and other processes for recycled products (including but not limited to drinking water buckets, transparent plates, lamps, container shells, environmental films, discs, etc.). Based on different recycling sources and quality levels, we design and classify PCR PCs for extrusion grade and injection grade, technological innovation breakthroughs, performance re optimization, and high-quality automated production and processing, providing customers with extrusion grade and injection grade PCR PC ® Particles. The company‘s products cover different colors and product series such as high molecular weight, medium molecular weight, low molecular weight, as well as colorless selection, blue transparency, and black, which can meet the different application needs of industry customers. At the same time, we can provide comprehensive customized system solutions and innovative solutions according to customer special requirements.

Product brand

Topcircle ®,

TcycleEP ®,

PCR PC ®,

Coastbound ® OBP,

FreeCBO2 ® (Zero carbon),

ITEcycle ®;

Product Features

Fine design and optimization control of rPC raw material sources and quality. Strict management of production and processing processes and technical quality standards, stable and sustainable product performance, and the ability to achieve full industry chain traceability;

Provide Carbon footprint, carbon emission accounting and other relevant data and certification;

We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements;

The product complies with RoHS/REACH/FDA standards and has passed the GRS/UL2809/TIV/ITE/"zero" carbon certification;

Provide "zero" carbon PCR PC ® FreeCBO2 ® (zero carbon products);

Can reduce or reduce carbon emissions by more than 91.3%, and some products have achieved "zero" carbon [cradle to gate].

Typical products

Product Application

The product is suitable for downstream deep processing modified granulation, as well as extrusion and injection molding. It can be used for various injection molded parts such as switch panels, consumer electronics, electrical enclosures, automobiles, building blocks, etc.

As one of the five major industrial plastics, PC materials have a wide range of applications. Therefore, the widespread application of PCR PC is even more necessary to enhance environmental protection. The use of green, low-carbon, and safe recycled materials cannot do without the efforts of the industry and the support of everyone.

-END-

If you see the above identification

Please remember that they are all our logos~