With the continuous progress of modern science and technology, especially the rapid development of new energy industry and 5G construction, countries around the world attach great importance to safety work, and the application of flame retardant materials is becoming more extensive, prompting people to have higher and higher requirements for the safety and fire performance of flame retardant materials. Among them, halogen flame retardant materials have high flame retardant efficiency and low dosage, becoming the world‘s largest organic flame retardant in terms of output and use.

The development of halogen-free flame retardants has gradually become a global trend

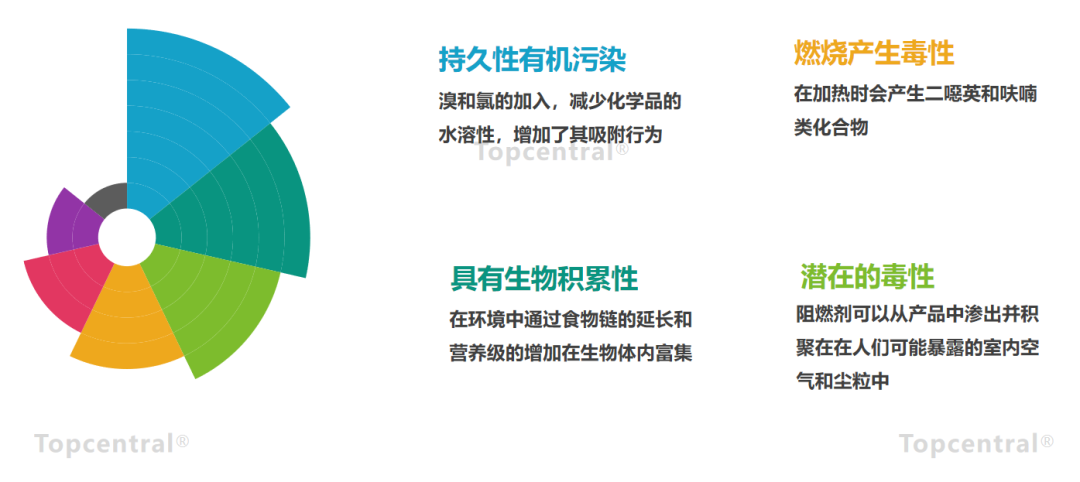

However, halogen flame retardants have increasingly obvious environmental protection and safety problems, such as the generation of corrosive and toxic gases, resulting in short circuits or corrosion of other metal objects; Cause air pollution and have a serious impact on the human respiratory tract. Countries around the world have issued a series of regulations and decrees, and have introduced prohibitions and restrictions on flame retardants in consumer products; Apple, Samsung, HP, Dell and other companies have promised to gradually stop brominated flame retardants, with strict requirements and even regulations: Br<900ppm; Cl<900ppm; Br+Cl < 1500 ppm。 Therefore, the development of halogen-free flame retardants has gradually become a world trend.

For electronic and electrical, automotive and instrumentation industries, such as in the electronics industry for the manufacture of parts requiring heat resistance, electrical insulation and high mechanical strength; Used in the automotive industry to manufacture lightweight, impact-resistant and friction-resistant parts; In the instrument industry for the manufacture of camera shells, instrument shells, various accessories, etc., rPET materials are widely used, halogen-free flame retardant rPET materials have become a research hotspot.

In response to this, Topcentral® launched new products and innovative solutions of environmentally friendly halogen-free flame retardant reinforced rPETBLend™.

Environmentally friendly halogen-free flame retardant reinforced rPETBLend™

Through the recycling, pretreatment and deep processing of waste PET, Topcentral® finally obtains high-end functional modified materials with high performance, high functionality and high added value, so as to realize the same level of substitution of products to virgin materials™. The whole production and preparation through 24h process inspection for quality control, vacuum deodorization, filter impurity removal, 24h performance monitoring and performance comprehensive testing, build product life cycle management and carbon footprint traceability, to achieve low-carbon and environmentally friendly production and preparation.

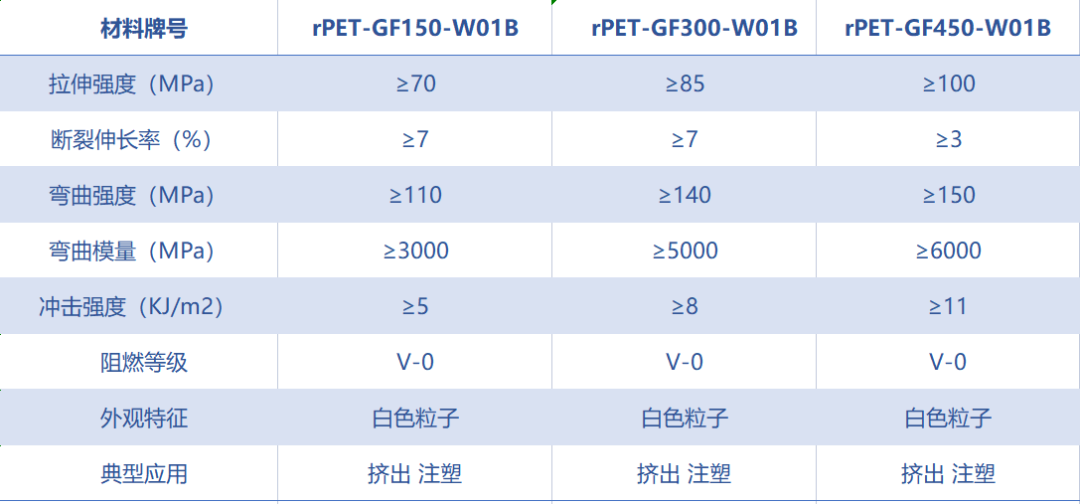

Topcentral® environmental protection halogen-free flame retardant reinforced rPETBLend™ products from post-consumer recycling, marine recycling and sea recycling water bottles, after sorting, crushing, cleaning and other processes, to prepare 100% PCR PET (TC-Rester® & OceanPET®) products, through enhanced flame retardant modification, prepared into glass fiber reinforced flame retardant rPET products, recycled content > 50%, environmental protection and safety, halogen-free and non-toxic.

Product features

◾ Low-carbon, environmentally friendly, non-toxic and safe

◾ Excellent mechanical properties and flame retardant properties

◾ Good dimensional stability, high stiffness, low warpage

◾ It has excellent high and low temperature resistance

Typical products

Application areas

Capacitor housing, ignition coil, switch, integrated circuit housing

-END-