————Product Application————

What is the pearl in the palm of contemporary times?

Of course it‘s a phone!

In daily life, a mobile phone can be said to be an indispensable part of the phone. In addition to sleeping time, it must always be necessary. If you don‘t look at your phone every few minutes, you will feel uncomfortable. Without your phone, you will feel inexplicable anxiety, confusion, loss, and even a little confused

I have a mobile phone in my hand. But with the bare machine in hand, it seems to lack some sense of security. I‘m either afraid it might scratch or fall, afraid it might get a little injured. So, the first reaction most people have when they get a phone is to buy a phone case first!

At present, the most common phone cases are mainly divided into three types: liquid silicone, TPU material, and PC material, with metal material, leather material, and carbon fiber material becoming increasingly rare. A good phone case not only protects the phone, but also decorates the phone and beautifies it.

Next, let‘s learn about the performance of three types of phone cases:

01

TPU material

Features: The texture is between liquid silicone and PC, with super strong wear resistance, excellent ozone resistance, good shock absorption effect, high hardness, high strength, good elasticity, low temperature resistance, good oil resistance, chemical resistance, and environmental resistance. It can be printed, with good hand feel and aesthetics. It is transparent and not easy to scratch, but the hand feel is relatively hard and easy to turn yellow;

02

PC materials

Features: Hard texture, good strength and toughness, strong impact resistance, easy dyeing, relatively light and thin, not affected by temperature, good creep resistance, stable size, high transparency, but the texture is the hardest and easy to scratch, transparent PC material is easy to turn yellow;

03

Liquid silicone

Features: Soft texture, good hand feel, good tear resistance, rebound resistance, yellowing resistance, thermal stability, water resistance, heat aging resistance, excellent weather resistance, moderate viscosity, easy processing, good breathability, good shock absorption effect, but opaque;

Among these materials, the performance of different materials varies. TPU and PC materials have transparent properties, especially TPU material, which is the most popular among consumers due to its moderate comprehensive performance, difficulty in scratching, and affordable price. Because TPU turns yellow, a large number of TPU phone cases are discarded every year. Topcentralhas modified these discarded TPU materials to become recycled materials.

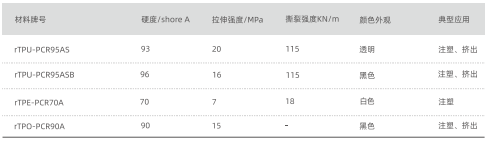

Topcentral® PCR TPU

Made by recycling, pre-treatment, and standardized granulation of polyurethane elastomer waste after consumption. We can provide customers with injection and extrusion grade TPU recycled particles, including transparent, gray, black, and designated colors, to meet the different application needs of industry customers. We can design and customize development according to customer specific requirements, including material technology solutions, supply chain recycling solutions, application solutions, designated certification and regulatory requirements, carbon emission management solutions, Chifeng Chain traceable blockchain, and closed-loop solutions for the entire industry chain.

Product Features

- Fine design and optimization control of raw material sources and quality, strict management of production and processing processes and technical indicators, stable and sustainable product performance, achieving full industry chain traceability;

- Specify product certification and regulatory requirements;

- Can provide relevant data and certification such as carbon footprint and carbon emission accounting;

- Closed loop solution for the entire industrial chain,Topcentral chiChain®Traceable blockchain

- The product is in its original color and covers the specified colors.

- We can provide comprehensive customized system solutions according to customer customization requirements

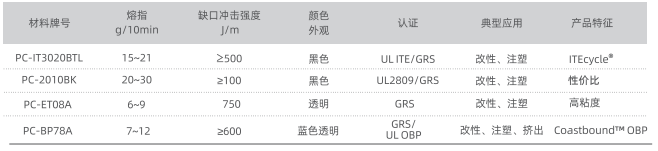

Typical products

Application direction

rTPU® Regenerated particles are 100% recycled plastic particles after consumption, with high purity and excellent mechanical properties, which can meet daily usage scenarios such as tool kit adhesive, cable protection, and roller preparation.

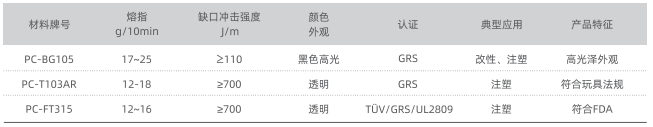

Topcentral® (PCR PC®)

It is a plastic particle prepared through processes such as pre-treatment and standardized granulation modification of recycled consumer products (including but not limited to drinking water buckets, transparent sheets, car lamps, container shells, lenses, optical discs, etc.). Based on different recycling sources and quality levels, design classification screening, technological innovation breakthroughs, performance re optimization, and high-quality automated production processing to provide customers with extrusion and injection grade PCR PC~particles. The company‘s products cover different colors and product series such as polymers, middle molecules, low molecules, as well as colorless transparency, blue transparency, and black, which can meet the different application needs of industry customers. At the same time, we can provide comprehensive customized system solutions and innovative solutions according to customer special requirements

Product brand

Topcircle®,

TcycleEP®,

PCR PC ®,

Coastbound ™ OBP,

FreeCB02® (Zero carbon),

ITEcycle®;

Product Features

- Fine design and optimization control of PC raw material sources and quality, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, achieving full industry chain traceability;

- The product complies with RoHS/REACH/FDA standards and has passed the GRS/UL2809/TUV/ITE/"zero" carbon certification;

- Can provide relevant data and certification such as carbon footprint and carbon emission accounting;

- Providing "zero" carbonPCR PC®FreeCBO2® (zero carbon products);

- Can reduce or reduce carbon emissions by more than 91.3%, and some products have achieved "zero" carbon [cradle to gate];

- We can provide comprehensive customized system solutions according to customer customization requirements

Application direction

The product is suitable for downstream deep processing modified granulation, as well as extrusion and injection molding. It can be used for various injection molded parts such as switch panels, consumer electronics, electrical enclosures, automobiles, building blocks, etc.