Topcentral®& Qimei

Recycled materials create recycled neutral pens

Whether it‘s a student or a worker

Who can leave the pen?

No one can do without it

(Listen to your words, listen to your words)

It is understood that there are over 300 million students in China who use at least one pen every month, which means that at least 3.6 billion discarded pens are generated every year. In addition, white-collar workers also use neutral pens, which will be discarded directly after use. There are currently two mainstream views on solving the problem of pen pollution, one is the recycling of pen materials, and the other is the natural degradation of pen materials. Regardless of the method, bold innovation is needed to adapt to the increasingly strict requirements of green development.

In response to the difficult problem of completing the entire recycling loop due to the small profit margin of pen materials recycling, in order to solve the customer‘s problem, Topcentral® Together with Qimei and two companies, we have created a pen made of recycled materials. The outer shell of this pen contains 75% recycled ABS material and solves the recycling problem after disposal. It is designed from the top port of recycled material recycling to achieve full industry chain traceability, further reducing the difficulty of recycling, improving the measurement of recycling, and better integrating renewable resources into the circular economy system, exploring green and sustainable development of resources.

Topcentral®& Qimei - made of recycled materials for neutral pens)

What is the entire recycling process for this pen material? Follow the editor and take a look!!!

Through the screening, classification, disassembly, and rough processing of various waste products such as discarded rice cookers, televisions and other small household appliances, PP based multi material combination toys or stationery, PP/PE basin barrels, ABS safety helmets, and coated parts in the early stage, and through different processing equipment, processes, and separation equipment to handle a wide variety of products, as well as the comprehensive performance of the products, ABS helmet material is ultimately selected PP material toys and other ABS materials are used as finished materials for processing in recycled material pens.

The first step in the entire process is to dismantle the recycled waste products and select the materials, which is also the most complex and cumbersome step.

Pre collection of ABS materials for helmets

Pre collection of PP toys and other ABS materials

Subsequently, after disassembly and crushing processing, the following recycled ABS recycled materials, PP toys, and other ABS recycled materials were obtained:

Crushing and processing of ABS material for helmets

PP toys and other ABS materials crushing processing

Finally, Topcentral® After on-site production and quality inspection, the final appearance, color palette, and performance of the two materials are as follows:

Appearance and color display of ABS recycled materials for helmets

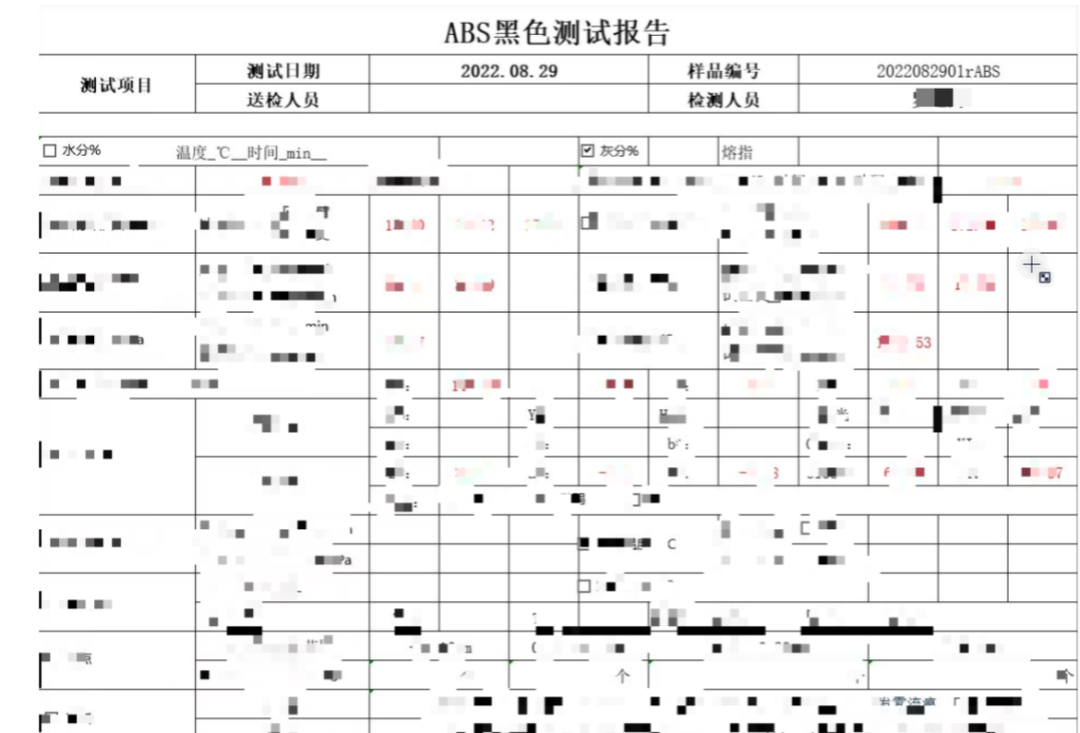

Test Report on ABS Recycled Materials for Helmets

Appearance and color display of PP toys and other ABS recycled materials

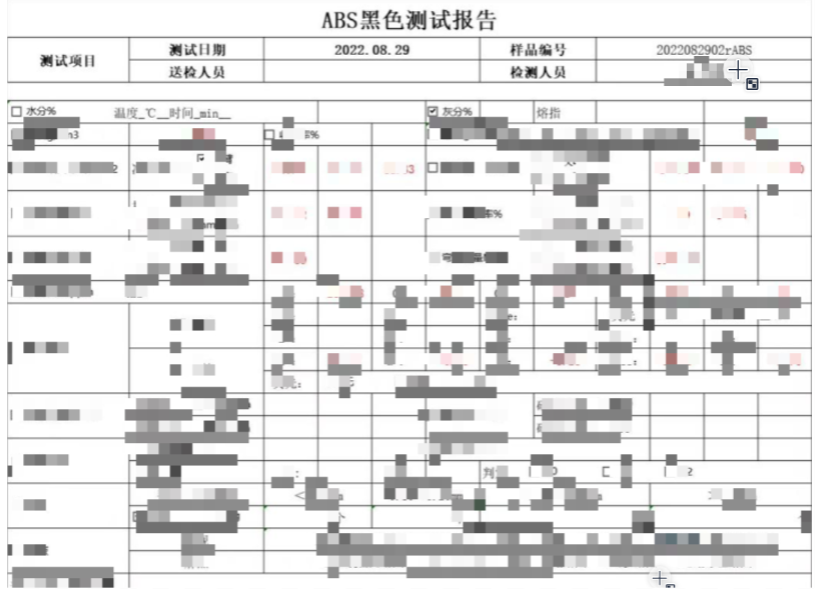

PP Toys and Other ABS Recycled Materials Test Report

After the materials have been fully verified, we will send all the raw materials to the factory where the pen is made for processing and manufacturing, and finally deliver this pen made of recyclable materials to the customer.

Topcentral® As a renewable materials enterprise, we have always been trying to use new methods, concepts, and technologies to promote green and environmentally friendly development. As one of the important key components of sustainable development in the future, renewable materials are a key component of Topcentral® PCR IBISS® rABS and PCR Ploypoy® Almost all categories of products such as rPP can provide comprehensive customized system solutions and innovative solutions according to customer specific requirements. What are the specific situations of these two products in terms of performance, "zero" carbon standards, environmental protection, and quality?

Topcentral®IBISS ® rABS

It is a plastic particle prepared through processes such as pre-treatment and standardized granulation modification of recycled consumer products (including but not limited to household appliances, communication equipment, pipes, plates, coils, consumer electronics, etc.). Based on different recycling sources and quality levels, design classification screening, technological innovation breakthroughs, performance re optimization, and high-quality automated production processing to provide customers with extruded and injection grade rABS particles. The company‘s products cover different sources of lotion method and bulk method, and can provide colors including but not limited to natural color, black, gray, white and other different color systems. It can meet the different application needs of industry customers and provide comprehensive customized system solutions and innovative solutions according to their special requirements.

Product brand

Topcircle ®,

TcycleGP ®,

IBISS ®,

Oceancycle ®,

Coastbound ™ OBP,

Appcycle ®,

FreeCBO2 ®,

ITEcycle ®;

Product Features

- Fine design and optimized control IBISS®The source and quality of raw materials for rABS, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, can achieve full industry chain traceability;

- The product complies with ROHS/REACH/FDA/Halogen Free standards and has passed the GRS/TUV/UL/SCS Global/ITE "zero" carbon certification/Coastbound ™ OBP;

- Can provide relevant data and certification such as carbon footprint and carbon emission accounting;

- Can reduce or reduce carbon emissions by more than 83.3%, and some products have achieved "zero" carbon [cradle to gate];

Providing "zero" carbon for IBISS® rABS FreeCBO2® (zero carbon) products;

- We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements.

Typical products

Application direction

The product is suitable for downstream deep processing modification granulation, extrusion molding, injection molding, and can be widely used in various product parts such as household appliances, electrical appliances, automobiles, packaging, daily chemical products, etc.

Topcentral® Ploypoy ® rPP

It is a plastic particle prepared from recycled and consumed products through processes such as pre-treatment and standardized granulation modification. Based on different recycling sources and quality levels, design classification screening, technological innovation breakthroughs, performance re optimization, and high-quality automated production and processing, providing customers with extrusion grade, injection grade blow molding grade rPP particles, colors including but not limited to natural color, black, white, etc., which can meet the different application needs of industry customers. At the same time, we can provide comprehensive customized system solution innovation solutions according to customer special requirements.

Product brand

Topcircle ®,

TcycleGP ®,

Baolibao ®,

Ploypoy ®,

Oceancycle®,

Coastbound ™ OBP,

FreeCBO2 ® (Zero Carbon)

Product Features

- Fine design and optimization control of the source and quality of rPP raw materials, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, and the ability to achieve full industry chain traceability;

- The products are mainly made of high-grade natural white PP, covering specified colors (including but not limited to black, white, etc.) and other products;

- The product complies with RoHs/REACH/FDA standards and has passed the GRS/TUV/SCS Global/Oceancycle ®plastic /Coastbound™OBP certification;

- We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements;

- Can provide relevant data and certification such as carbon footprint and carbon emission accounting, Oceancycle®plastic Certificate OBP Certificate;

- Can reduce or reduce carbon emissions by more than 70%, and some products can achieve "zero" carbon [from cradle to gate];

Typical products

Application direction

The product is suitable for blow molded products such as cosmetic bottle bodies, extruded films/plates, various injection molded parts, and other fields.

-END-

If you see the above identification

Please remember that they are all our logos~