If you want to improve the quality of your home, the editor believes that besides the dazzling furniture, carpets are the most worth considering. A good carpet can effectively enhance the quality of your home. Moreover, carpets are particularly practical, with good cushioning, decoration, activity convenience, and sound reduction and noise reduction effects.

Among artificial fiber materials, nylon carpets have become ideal materials for carpet production due to their advantages such as easy cleaning, high wear resistance, strong toughness, softness, insect resistance, mold resistance, corrosion resistance, and low pilling.

Recently, New Zealand‘s sustainable home brand Noho Group has reached a partnership with Aquafil Group, a leading global Italian textile manufacturer, due to Aquafil Group‘s ECONYL® Regenerated nylon is completely regenerated from nylon 6 waste through chemical recovery methods, and its performance is consistent with that of petroleum based nylon. ECONYL® Recycled nylon has been widely used to make carpets, swimwear, Sportswear and accessories.

After rigorous comparison, they believe that ECONYL® Regenerated nylon is very in line with their demand for sustainable home concepts, and the two have decided to reach a long-term cooperation to jointly protect the environment.

Recycled nylon carpet

It is understood that there are two main sources of recycled materials for recycled nylon. One is to recycle waste carpets by disassembling the surface yarn, backing, and other parts of the waste carpet, identifying, separating, cleaning, and granulating them for production, and then processing them. However, the difficulty lies in the fact that waste carpets often have adhesives, making it difficult to clean them thoroughly during the cleaning process, Will cause durability and dimensional stability to be affected to a certain extent;

Another type of recycling mainly comes from waste fishing nets, fabric waste, industrial waste plastics, and other waste. Here, recycling materials makes the treatment method for waste nylon more scientific and standardized.

With the continuous enhancement of environmental awareness in China, the demand for recycled materials continues to expand, and recycled products are beginning to be popular among the public.

A good carpet has strict requirements for material, craftsmanship, and technology. If the material is not good, everything is useless. Compared to the recycling of nylon from discarded carpets, the current method of recycling discarded fishing nets is very mature, so it has more advantages in the recycling process. Of course, recycling discarded carpets is also a very important matter.

Topcentral® As a renewable material enterprise, we have been promoting sustainable development by recycling waste materials. Currently, Topcentral® PCR Nairong® Our recycling technology is very mature, and we have rich experience in addressing the needs of different customers. For carpet applications, our PCR Nairong® The series of products can provide comprehensive customized system solutions and innovative solutions according to customer special requirements, achieving product performance satisfaction.

picture

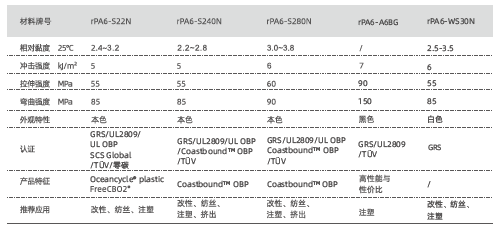

Topcentral® PCR Nairong ®

It is a PCR PA6 particle prepared through pretreatment and standardized particle modification process based on the recycled fishing net, automobiles, low-voltage appliances, etc. after consumption. The appearance is mainly in natural colors and black, and we can provide customized products for customers, such as Oceancycle, which is recycled by SeaHiPot®), It can meet the numerous needs of injection molding, modification processing, textile spinning, extrusion and other fields, and can provide comprehensive customized system solutions and innovative solutions according to customer special requirements.

Product brand

Topclcircle®,

TcycleEP®,

Nairong®,

Oceancycle®,

Coastbound® OBP,

FreeCB02® (Zero carbon),

Ocean Partners ™ Ocean Partner®;

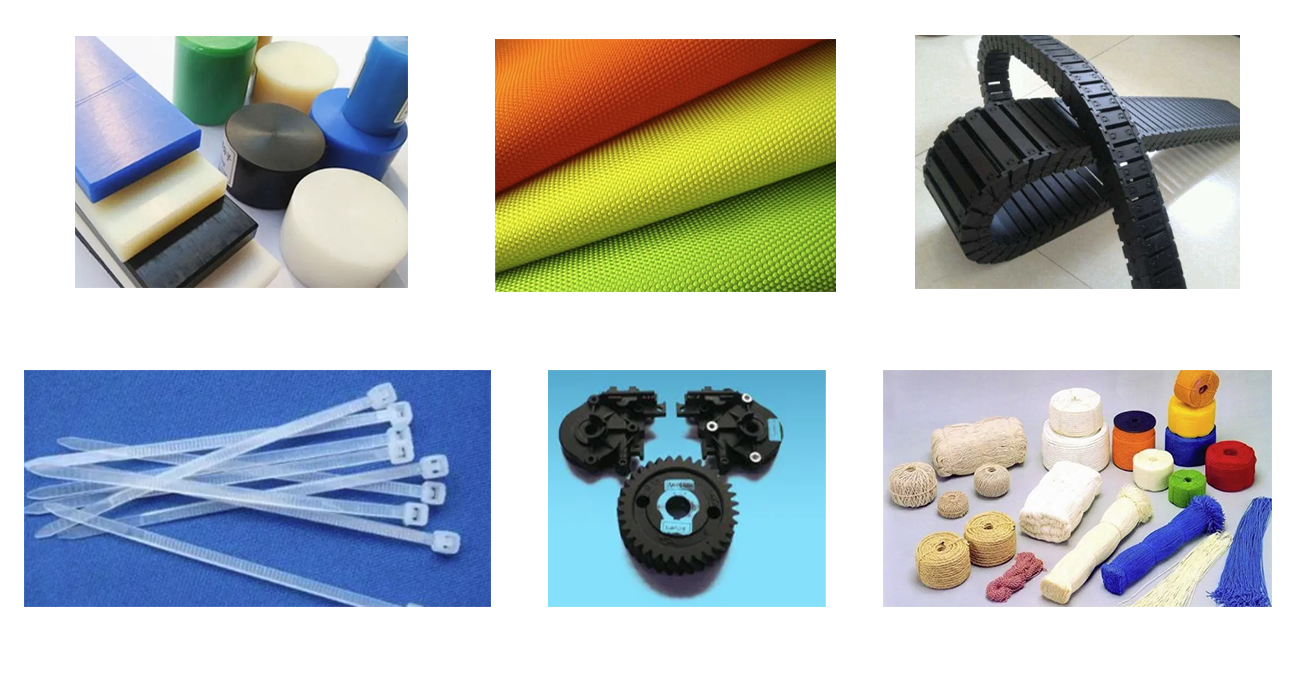

Typical products

Product Features

Fine design and optimized control rPA6 and Oceancycle® The source and quality of raw materials, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, can achieve full industry chain traceability;

The products are mainly white particle products, while black particle products are mainly made of recycled glass fiber reinforced modified materials after consumption;

Provide Carbon footprint, carbon emission accounting and other relevant data and certification;

We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements;

The product meets ROHS/REACH standards and has passed GRS/UL OBPUL2809/TUV/OP/Coastbound® OBP/FreeCBO2® /Carbon neutral/Carbon footprint/SCS Global certification work together to build a pioneering and open marine partner ™ Ocean Partner® Plan; High purity and transparency;

Provide a ‘zero‘ carbon Oceancycle® FreeCB02® (zero carbon) products;

Some products that can reduce or reduce carbon emissions by more than 92.3% have achieved "zero" carbon [from cradle to gate].

Application direction

The product is suitable for downstream deep processing modification granulation, and after modification, various mechanical parts can be made. It is also suitable for injection molding, spinning and other applications.

-END-

If you see the above identification

Please remember that they are all our logos~