Can you accept environmentally friendly recycled curtains?

Recycled nylon curtains

Low carbon, environmentally friendly, wear-resistant, and sturdy

Recently, the temperature in summer has skyrocketed, finally ushering in the weekend. As a result, I accidentally slept until noon and was directly awakened by the sun. The restless sound outside the window passed through the room, making it impossible to sleep in. Then, as the curtains were pulled, suddenly, it seemed like the whole world was quiet.

Whether it‘s day or night, as long as the curtains are closed, it always makes people feel an inexplicable quietness, and the sleep time seems to have increased.

Can‘t help but think, besides protecting privacy, do curtains also have the function of sound insulation and sleep aid?

Yes, soundproof curtains can achieve a sound insulation level of about 10 decibels, which indeed has a sound insulation effect. Moreover, curtains can also isolate external light and reduce the interference of external light on our sleep. But most of the curtains used in daily life do not have such good sound insulation effect.

In fact, a suitable curtain not only needs to be easy to weave, but also has a wide range of applications, and the most important thing is its performance.

Those who have experience in decoration will definitely search for information about curtains online. In many short videos, there is often an opening line: "Don‘t choose XX material, choose polyester, it has good light blocking and elasticity, and has many advantages and high cost-effectiveness

Indeed, polyester has many advantages, but the shade and thickness of the curtains can affect their light blocking effect, which is not directly related to the material. As consumers, we should be aware that the functions of different curtains will definitely vary, and only based on our specific usage environment can we choose satisfactory products.

Most of the curtains on the market are made by blending artificial fibers such as nylon and polyester, and different textures such as linen, cotton, silk, and flannel are also made by different processes and material ratios.

Nylon material, as the most commonly used plastic in the textile industry, has a wide range of applications in curtains. Moreover, with the improvement of environmental awareness and the continuous maturity of recycled plastic technology, many manufacturers have used various recycled materials on curtains, aiming to achieve the dual effects of environmental protection and resource utilization through recycling technology. Nylon curtains are generally blended with wool, and their advantages lie in their excellent wear resistance and firmness, low density, light fabric, fatigue resistance, stable chemical properties, good elasticity and elastic recovery, and good moisture absorption. They are used in fields such as fishing nets, low-carbon, ropes, conveyor belts, and screens.

For example, Medit green curtains are made of recycled nylon called Econyl, which is used in both yarn and fabric, and can be recycled indefinitely without generating plastic waste.

Medit Green Curtain

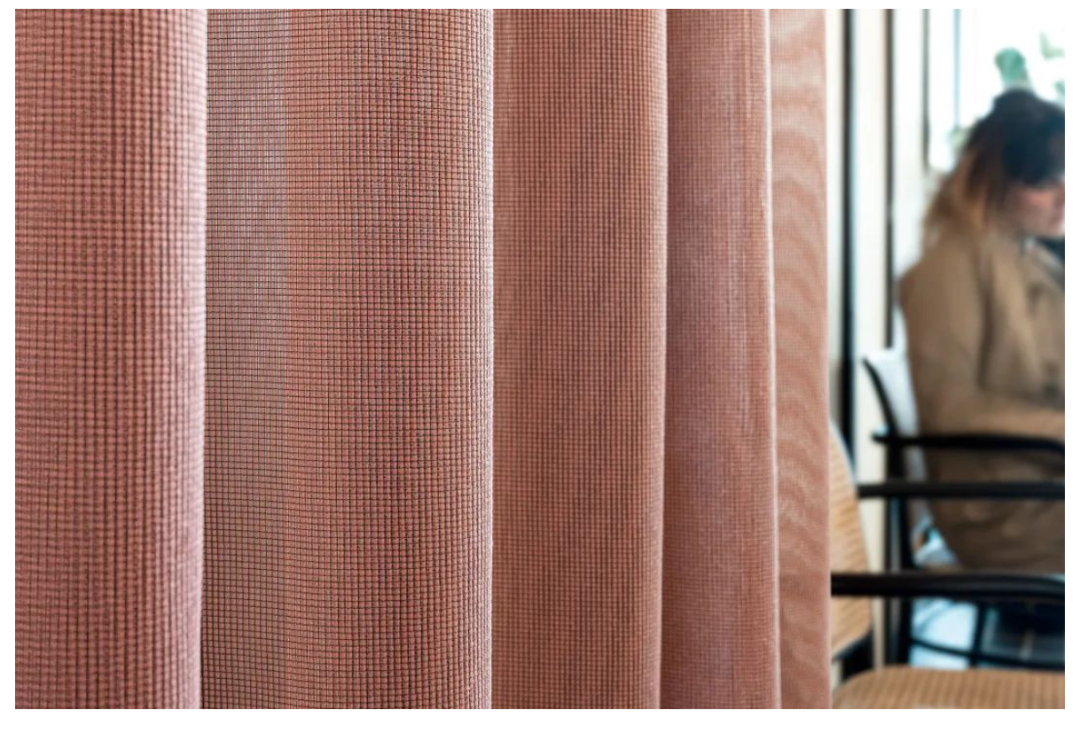

In addition to recycled nylon, some manufacturers also use recycled PET on curtains, such as VESCOM‘s eco-friendly curtains - Teon&Nias2086, whose micro grid structure of the curtain faces weft yarns made of 100% recycled PET.

Nias2086 curtains

The continuous application of recycled materials in the textile industry has further promoted the development of recycled materials. It is particularly important to improve the quality of recycled materials and enable consumers to choose recycled curtains with confidence.

Using recycled and environmentally friendly materials in daily life seems really cool. It can not only protect the environment and reduce carbon emissions, but also choose satisfactory products and subconsciously improve one‘s environmental awareness, which can be said to be many things in one go.

It is undeniable that recycled environmentally friendly materials do have some drawbacks, such as poor breathability of nylon materials, poor heat and light resistance, alkali resistance but not acid resistance. Therefore, it is necessary to pay attention to washing and ironing conditions.

But this can be achieved through customized innovative material solutions, such as Topcentral® The product brand is Nairong ® RPA6-S22N recycled nylon material, processed by Topcentral® The continuous experiments of R&D personnel can meet the application in many fields such as modification, spinning, injection molding, extrusion, etc. It has become a renewable material with excellent performance, which can meet the multiple use in the textile field, such as sportswear fabrics, curtain fabrics, and mechanical parts. Topcentral® R&D team has rich experience in innovative solutions for new materials, and can provide all-round customized systematic innovative solutions according to the special requirements of customers, Achieve target performance requirements.

Topcentral® Nairong® rPA6

It is a PCR PA6 particle prepared by pretreatment and standardized granulation modification process based on the recycled fishing net, automobiles, low-voltage appliances, etc. after consumption. The appearance is mainly in natural colors and black, and we can provide customized products for customers, such as ocean recycling products (0Cycle), which can meet the numerous needs of injection molding, modification processing, textile spinning, extrusion, and other fields. At the same time, we can provide comprehensive customized system solutions and innovative solutions according to customer special requirements.

Product brand

Topclcircle®,

TcycleEP®,

Nairong®,

Oceancycle®,

Coastbound® OBP,

FreeCB02® (Zero carbon),

Ocean Partners ™ Ocean Partner®;

Typical products

Product Features

Fine design and optimized control rPA6 and Oceancycle ® The source and quality of raw materials, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, can achieve full industry chain traceability;

The products are mainly white particle products, while black particle products are mainly made of recycled glass fiber reinforced modified materials after consumption;

Provide Carbon footprint, carbon emission accounting and other relevant data and certification;

We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements;

The product meets ROHS/REACH standards and has passed GRS/UL OBP/UL2809/TUV/Oceancycle® OP/Coastbound ® OBP/FreeCBO2® /Carbon neutral/Carbon footprint/SCS Global certification work together to build a pioneering and open marine partner ™ Ocean Partner® Plan;

High purity and transparency;

Provide a ‘zero‘ carbon Oceancycle® FreeCB02® (zero carbon) products;

Some products that can reduce or reduce carbon emissions by more than 92.3% have achieved "zero" carbon [from cradle to gate].

Product Application

The product is suitable for downstream deep processing modification granulation, and after modification, various mechanical parts can be made. It is also suitable for injection molding, spinning and other applications.

--END--

If you see the above identification

Please remember that they are all our logos~