Recycled PET&Clothing Applications

- PCR PET -

Diesterate ™ TC Rester®

PET can maintain excellent physical and mechanical properties in a wide temperature range, with excellent fatigue resistance, friction resistance and aging resistance, outstanding electrical insulation, stable for most organic solvents and Mineral acid, low production energy consumption, and good processing performance. Therefore, PET has been widely used in plastic packaging bottles, films, Synthetic fiber and other fields.

-01-

As a disposable product, the vast majority of PET is discarded after use, and the recycling rate is also low, especially with a large amount of waste and a wide range of pollution. How to regenerate and recover waste PET, as well as how to achieve textile performance after recycling, has always been a challenge. In the long run, the recycling and utilization of PET is of positive significance in protecting the environment, saving resources, and even changing China‘s long-term dependence on fossil resources to promote sustainable development.

Most people may still stay in the field of packaging bottles for their understanding of PET, but in fact, PET has a wide range of uses and its recycling is of great significance, especially in the textile field. Recycled PET is the most commonly used, and can be applied by spinning the recycled recycled PET particles.

What material is recycled PET after spinning?

It is recycled polyester, as is well known, which is one of the most widely used materials in the textile field.

Why is the textile field the most widely used?

Regenerated PET mainly comes from discarded plastic bottles. Due to the strict health and hygiene requirements of packaging bottles, recycled PET is rarely used in packaging bottles. However, recycled PET has excellent spinning performance, such as smooth surface, high luster, good coloring, wear resistance, dimensional stability, low wear, high hardness, good electrical insulation, low temperature resistance, non-toxic, low water absorption, weak acid resistance, and organic solvent resistance. The recycled PET fiber processed in melt spinning equipment is one of the ideal materials in the field of clothing fabrics.

-02-

Topcentral® Deuterol ™ TC-Rester® rPET has a product that is particularly suitable for spinning, with the brand name rPET-PCR70A.

Of course, recycled PET also has its own drawbacks: it is not resistant to hot water immersion and alkali.

Only food grade recycled PET materials can be used again to produce food grade packaging containers through the recycling process. For example, Pepsi launched the "Pepsi Recycling PET Bottle Campaign" at the official press conference held in May this year, and announced that PepsiCo will become the first company in the Thai soft drink market to use 100% rPET bottles as its beverage packaging.

Having said so much, are there any cases of recycled PET used in clothing?

Uniqlo, a famous Japanese clothing brand, launched a series of spring and summer commodities of "Doraemon Sustainable Development Mode" made of 100% recycled fabrics on this World Environment Day, including "Doraemon Sustainable Development Mode" T-shirts (two designs), children‘s T-shirts and portable bags. These three sustainable commodities of Uniqlo are made of recycled polyester PET.

Doraemon Sustainable Product Series

Doraemon Sustainable Product Series

In fact, whether it is Uniqlo or other garment enterprises, an environmentally friendly, renewable and sustainable garment can be successfully launched and finally handed over to consumers. It is inseparable from the efforts and efforts of such renewable enterprises as Topcentral. It is they who take root in the renewable industry, constantly improve the performance requirements of renewable materials, promote the experiment and production of renewable materials, and meet the requirements of clothing and textile.

The difficulty of regenerating PET lies in the following points:

- The label issue during the recycling of pet bottles, as well as the adhesive used for the label, can cause difficulties in back-end processing.

- The recycling of oil bottles in PET plastic products is inconvenient. During recycling and regeneration, mixing and recycling of oil bottles can easily form cross contamination. In the crushing and cleaning process, the cost of sewage treatment is high, difficult to treat, and the value is low.

- The design of PET bottle handles, aluminum mouth, rubber sealing pads, etc. to some extent increases the difficulty of PET bottle recycling.

- Additives affect the recycling of PET plastic bottles. Adding various additives to bottles makes it difficult to determine whether they meet the standards for food contact grade materials, which can have a significant impact on PET recycling.

- Colored PET plastic bottles affect recycling efficiency, reduce the value of recycled products, have low market acceptance and low prices, and have a narrow range of product applications.

- PET is modified by blending with other resins, making it difficult to separate the composite material.

Each of the above difficulties, if not addressed properly, will have a significant impact on the quality of PCR PET products, and Topcentral‘s diester ™ The reason why TC rester rPET-PCR70A can meet textile requirements is due to the research and development of PCR PET technology by strong researchers, solving recycling difficulties through our technology, and strictly controlling product quality to meet the performance requirements of PCR PET in the textile field, achieving the functional improvement of PCR PET.

-03-

Topcentral® TC-Rester ™ rPET

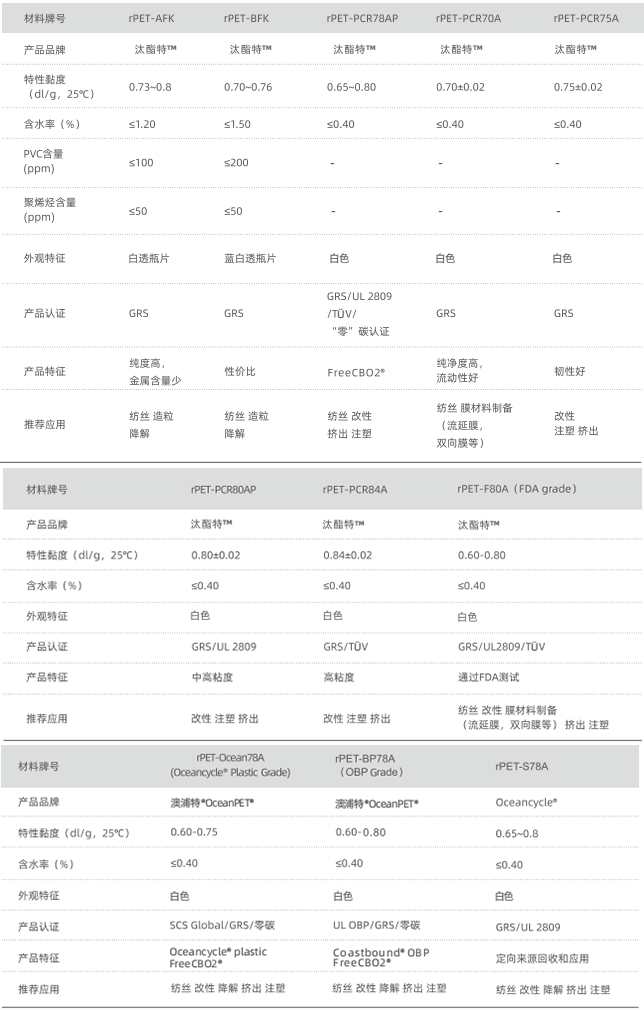

It is based on post-consumer recycled water bottles, which are preprocessed to obtain rPET bottle chips or extruded and granulated modified rPET particles. Based on different recycling sources and quality levels, it is designed and classified for screening, technological innovation breakthroughs, performance optimization, and high-quality automated production and processing. It provides customers with rPET particles of extrusion waste, casting film level, bidirectional film level, blow molding level, and injection molding level, covering medium to low viscosity, medium viscosity High viscosity and other product brands comply with RoHS/REACH standards and have been certified by GRS/TUVL/UL2908/SCS Global. Some products have passed FDA testing. At the same time, we can provide customers with a series of 0ceancecl® products that are suitable for ocean oriented materials (0BP) and ocean plastic (0P) recycling. It can meet the different application needs of industry customers and provide comprehensive customized and innovative solutions based on their special requirements.

Product brand

Topcircle®,

TcycleGP®,

Diesterate ™,

TC rester®,

FreeCB02® ("Zero" Carbon),

OceanPET®,

Textcycle® Oceancycle®,

Coastbound®OBP,

Lakecycle®,

Ocean Partner®.

Typical products

Product Features

Fine design and optimized control of diester ™ TC-Reaster®rPET and OceanPET® raw material sources and quality, strict management of production and processing processes and technical quality standards, stable and sustainable product performance, and can achieve full industry chain traceability;

With high purity and transparency, it can provide Carbon footprint, carbon emissions accounting and other relevant data and certification;

We can provide comprehensive customized system solutions and innovative solutions according to customer customization requirements

The product meets the RoHS/REACH standard, and has passed the GRS/UL2809/ULOBP "zero" carbon FreeCBO2®/Carbon footprint SCS Global/carbon neutral certification. Some brands have passed the FDA test;

Provide Aopu Te OceanPET products that meet Oceancycle OP and Coastbound OBP certifications, and jointly build Ocean Partner, Ocean Partner ™ Circular Green Plan;

Provide "zero" carbon diester ™ TC Rester® rPET, Oceancycle®, OceanPET®FreeCBO2®("zero" carbon product);

It can reduce or reduce carbon emissions by over 77.7%, and some products have achieved "zero" carbon [from cradle to gate].

Application direction

RPET particles cover brand names such as medium low viscosity (0.70dL/g), medium high viscosity (0.75dL/g and 0.8dL/g), high viscosity (0.84dL/g), and special viscosity (0.85dL/g-1.1dL/g) launched in 2023, and can be applied in multiple application fields such as film, sheet, packaging containers, and chemical fibers.

-END-

If you see the above identification

Please remember that they are all our logos~