Not long ago, the "CHINAPLAS 2025 International Rubber and Plastic Exhibition" was held in Shenzhen. At the exhibition, a special viewing benefit - an environmentally friendly pen made of recycled floating balls from Ningbo's "Ocean Partner" - became a popular check-in item.

It is understood that this environmentally friendly pen is made of discarded floating balls as raw materials and has been carefully designed and processed to give it new practical value. With the continuous development of the social economy, limited Earth resources are gradually being depleted, and circular economy is bound to be one of the main themes of future industries. It may seem like a simple pen, but it actually contains our 'Ocean Partner''s profound understanding and innovative practice of environmental protection concepts, "said Ma Yiming, initiator of the" Ocean Partner "project and founder and CEO of Ningbo Jianfeng New Materials Co., Ltd.

During the exhibition, the "Report on the Development of China's Recycled Plastics Industry (2024)" was released. As one of the core compilation units, Jianfeng ® Since its establishment, it has been committed to promoting plastic recycling and low-carbon economic development, with multiple independent intellectual property rights covering research and development of new materials, optimization of production processes, and other aspects, injecting cutting-edge technological insights and practical cases into the report.

Currently, Jianfeng ® Four major product lines have been formed, namely Taosu, Bida, Baidekang, and Kaisa, covering almost all types of plastic products. These high-performance recycled materials are widely used in various fields such as 5G fiber optic communication, consumer electronics, automotive industry, household chemicals, clothing and apparel. Low carbon recycled materials often require performance reduction to achieve recycling, and we have successfully achieved stability in material performance and peer regeneration through advanced recycling technology, AI algorithms, ultra clean filtration technology, and special functional modification technology, expanding their application scenarios and boundaries. ”Ma Yiming stated.

In Topcentral ®, Various sources, types of materials, and qualities of waste recycled plastics, after systematic production processes and technological innovations such as recycling, pretreatment, extrusion processing, and modification, become recycled plastic pellets that can continue to meet processing and application in various industries and products ® Topcircle ®)

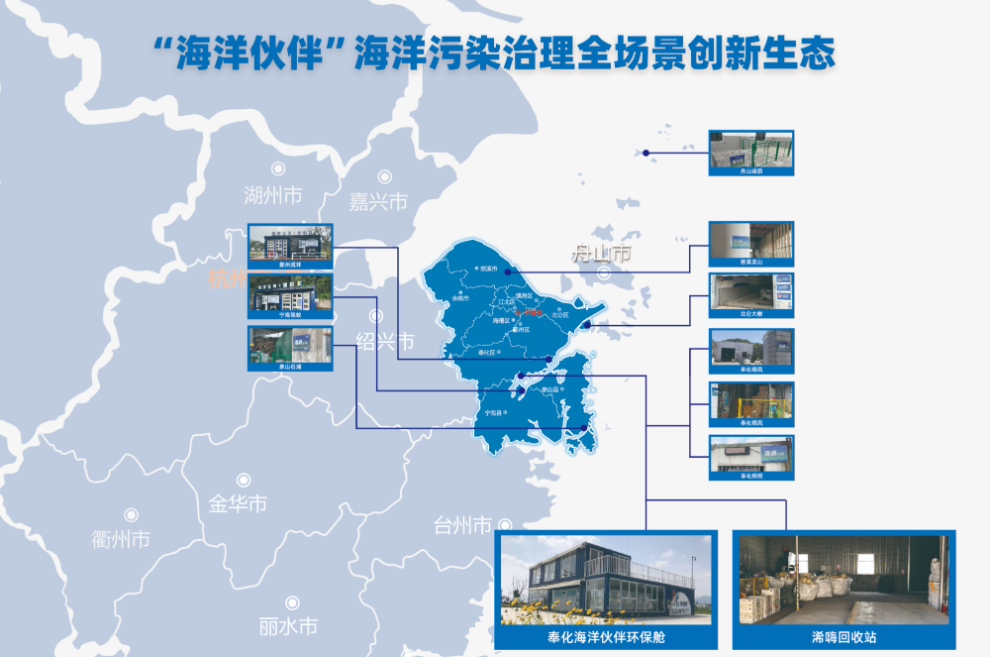

And these recycled plastic particles undergo processes such as deep processing and 3D printing terminal applications, ultimately transforming into products that combine beauty and practicality. The "Ocean Partner" environmental protection product cabinet is full of smart electric toothbrushes made from fishing baskets, baseball caps made from fishing nets, T-shirts made from plastic bottles from sea drifters... They all have an "identity tag" labeled with carbon reduction data. With a scan on their mobile phones, consumers can understand the source and production process of the marine plastic waste used in the product.